15591, 46019

Business Type:

Limited Company

Business Range:

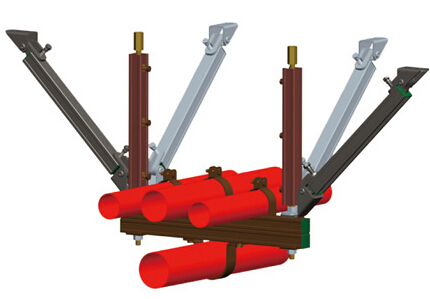

Cable tray, steel conduit, seismic bracket and v,

Management System Certification:

Terms of Payment:

LC, T/T

OEM/ODM Availability:

No

Trial Member

1 years

Audited Supplier