| Purchase Qty. / Reference FOB Price | |

|---|---|

| 1 piece | US $ |

| Production Capacity: | 5 |

|---|---|

| Payment Terms: |

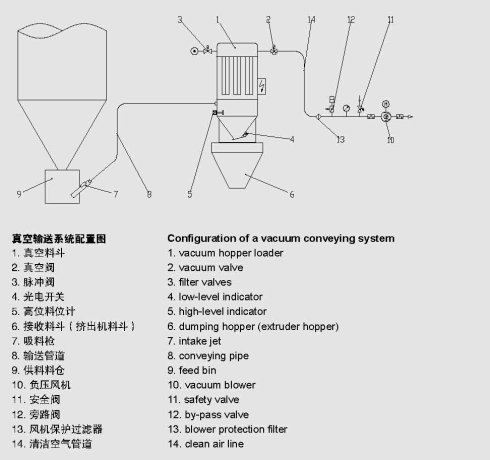

Vacuum feeding machine, also known as vacuum suction machine, vacuum feeder, negative pressure suction machine, vacuum feeding system, etc. Used for feeding extruders or other plastic processing machinery, or for feeding storage equipment such as hoppers and silos. Used for automatically feeding powdered, granular, flaky, or dusty granular materials to processing machinery or hoppers. It can also be used as a material separation device in negative pressure conveying systems. Can be used independently, with its own independent control system and a vacuum pump; It can also be used in central feeding systems, using a large vacuum pump to drive several or dozens of systematic vacuum feeders, and controlled by a control system. In large-scale production, this method is often used, which has the advantages of low cost, energy saving, and labor saving.

Working

principle

During

the operation of the vacuum pump, negative pressure is generated, which creates

a high-speed airflow in the suction nozzle and pipeline. The material is sucked

into the storage hopper of the feeding machine from the suction nozzle, and the

control system cuts off the negative pressure. Under the action of gravity, the

material falls into the designated equipment.

Product Features

The VLG series vacuum suction machine produced by our company adopts German technology and is specially designed for powder or mixed granular materials in powder. It is used as a feeding device for powder and adopts a negative pressure pneumatic conveying system, including a pulse compressed air back blowing bag filter and a flap valve discharge device. It has the characteristics of stable use, reliable performance, and maintenance free.

▲ Efficient Compressed Air Backblowing Bag Cleaning System

The filtering unit can be disassembled as a whole, making it easier to repair and replace the bag and change the color of the material

The parts that come into contact with the material are all made of stainless steel material

The discharge device can be equipped with a pneumatic cone valve or a gravity directional valve

The pipeline and control cables have been connected at the factory

▲ The large filtration area is particularly suitable for powder use

▲ Expanded discharge port

▲ Operating temperature: -10 ℃ to+80 ℃

PHONE:13776249631

EMAIL:cai-yz@163.com

QQ:759080241

Contact Us | User Agreement | Privacy Policy | 加入會員

Service Tel: (+86)0571-87774297